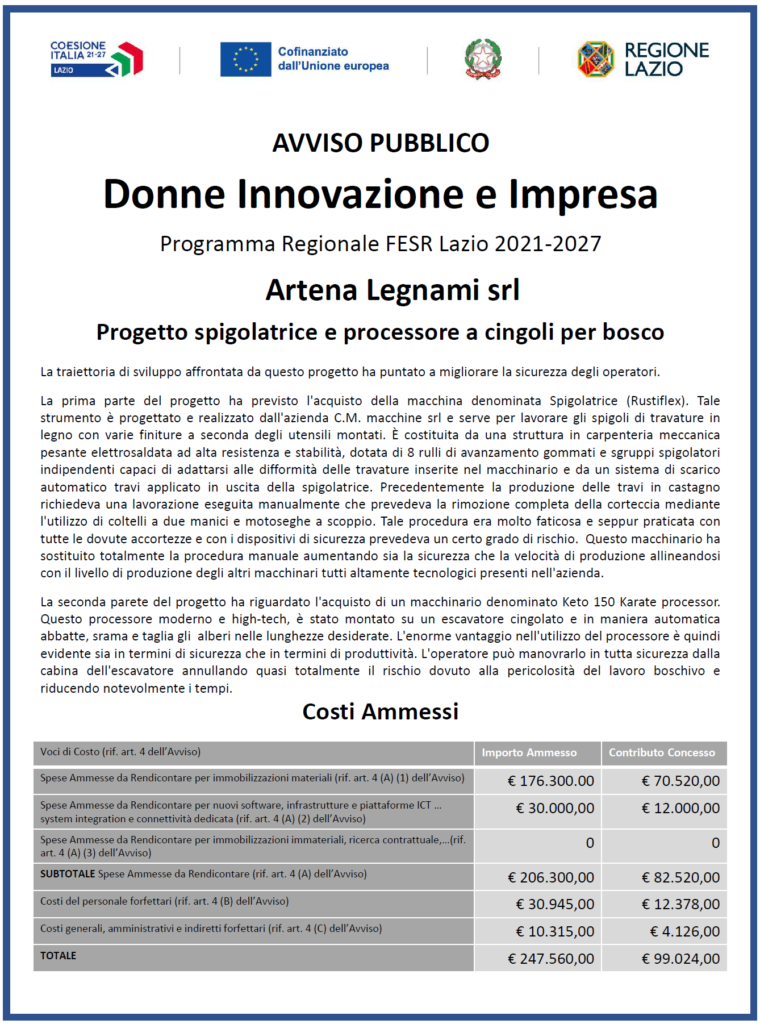

WOMEN, INNOVATION AND BUSINESS

Project: Edge Processor and Tracked Processor for Forestry

The development trajectory addressed by this project aimed to improve operator safety.

The first part of the project involved the purchase of a machine called the Spigolatrice (Rustiflex).

This tool is designed and manufactured by the company C.M. Macchine Srl and is used for processing

the edges of wooden beams with various finishes, depending on the tools installed. It consists of

a heavy-duty welded mechanical structure with high resistance and stability, equipped with 8 rubberized

feed rollers and independent edge processing units capable of adapting to the irregularities

of the beams fed into the machine. It also features an automatic beam discharge system applied at the output of the edge processor.

Previously, the production of chestnut beams required manual processing involving the

complete removal of bark using two-handled knives and combustion chainsaws.

his procedure was labor-intensive and, despite being carried out with all necessary precautions and safety devices,

still involved a certain degree of risk. This machine has entirely replaced the manual procedure,

increasing both safety and production speed, while aligning with the production levels of

the company’s other highly technological machinery.

The second part of the project involved the purchase of a machine called the Keto 150 Karate Processor.

his modern and high-tech processor was mounted on a tracked excavator and can automatically fell, delimb, and cut trees to the desired lengths.

The significant advantage of using the processor is evident both in terms of safety and productivity.

The operator can control it safely from the excavator cabin, almost entirely eliminating the risks

associated with hazardous forestry work and significantly reducing processing times.