THE BEST CHESTNUT WOOD PRODUCT

What is so special about solid wood compared to other market productions?

Laminated wood, engineered wood, hardwood products (that’s often confused with solid wood) are certainly interesting solutions for any kind of application (furniture, fixtures, structural use, etc.) but solid wood deserves a special place among the best materials for green building and indoor and outdoor furniture.

To really understand the 7 extraordinary properties of Solid Chestnut wood we need to start with a little introduction about the inside natural structure of this timber. Let’s cut a piece of Sweet Chestnut and take a look inside!

The morphology is extremely complex. In fact, dissecting a trunk we can recognize different parts with very peculiar characteristics. In particular, the most peripheral part of the examined section is characterized by a lighter coloration and it is called sapwood. This section is connected to a darker central portion that is called heartwood and this one is used to create solid wood products.

The sapwood, in fact, is much less resistant and subject to the external attack by fungi and insects, whereas the heartwood is generated through a chemical transformation of the cells from the sapwood and it does not have weaknesses. This feature makes the heartwood the best choice in many situations.

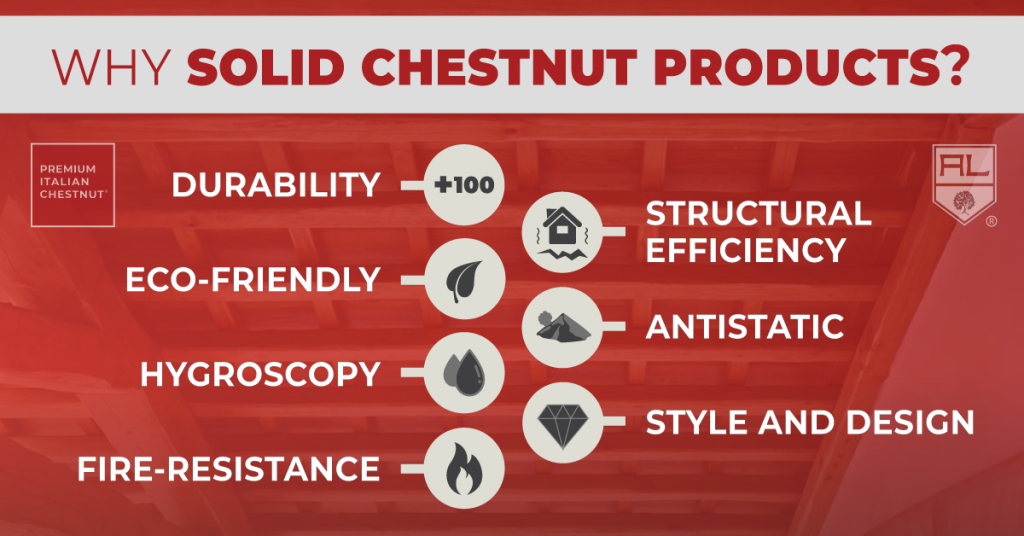

The 7 Qualities of Solid Chestnut Wood

Chestnut wood in the solid form has unique characteristics that make it extremely good and versatile in several applications. Let’s finally find out why it is considered one of the best materials on the market:

1) Durability. Chestnut wood is one of the most durable and resistant wood species in nature, by itself – see the high concentration of tannin inside (read the article The Power of Tannin, to learn more). Its solid form production significantly increases its life cycle over time. In fact, even when placed outdoor in extreme weather conditions, it can be surprisingly durable.

We can prove the fact just visiting all the historical works and structures in good conditions, made of solid wood, that can be admired even today after more than 4000 years since they have been created (such as structures and artifacts in the Pharaohs tombs).

2) Eco-friendly. The today regulations recommend the use of materials with a low environmental impact and which respond to the problems of bio-sustainability that unfortunately afflict the entire world. Solid Chestnut wood fits this profile because it is a solution with a low ecological impact due to its renewability. It is a 100% pure, regenerable and recyclable product, known on the market as “wood par excellence”.

3) Hygroscopy. The ability of a material to retain and repel moisture through a continuous exchange from its interior to its exterior. This peculiarity allows solid wood to establish an equilibrium with the surrounding environment by absorbing or releasing water vapor in the area. The degree of hygroscopy of solid chestnut makes it extraordinarily suitable for this phenomenon thanks to its porous and flexible configuration and it also allows the continuous storage of moisture without altering the state of the wood product over time.

4) Fire-resistance. Let’s dispel the myth of the high flammability of wood because the reality is quite different! Due to its conformation, solid chestnut wood registers very high standards (Italian REI measures) in terms of mechanical resistance to fire, even higher than masonry or reinforced concrete structures.

First of all, a solid wood structure guarantees what is called carbonation: when subjected to a direct flame, the wood begins to burn but once it reaches 240°C it starts a process of “carbonization” of the outermost layer protecting the innermost part like a shield, thus preventing the resistant section from shrinking for a very long time. Secondly, because of its hygroscopic capacity, it tends to accumulate so much moisture inside to further slow down the carbonization.

5) Structural Efficiency. Solid Chestnut is also suitable for the creation of complex and mixed structures. Thanks to the implementation of steel or concrete cables, in fact, it offers excellent levels of reliability. The application in anti-seismic constructions, is also a very important aspect. Its use is preeminent in areas of high seismic risk because of its behavior towards wave stimulation.

6) Antistatic. Unlike other materials (such as plastic), wood has antistatic properties because the surface of products tends to repel dust, debris and other allergens. This property make the living environment cleaner and safer especially for people with respiratory problems or dust mite allergies, whether the solid wood comes as a structural or furniture product.

7) Style and design. Private or public buildings with structural elements made of solid chestnut wood reproduce a particularly welcoming and fascinating environment. The natural appearance of solid wood and the unique coloring of Chestnut generate an extraordinarily calming effect to people and create very pleasant indoor climatic conditions: a sense of peace and relax that helps revitalize the nervous system and consequently strengthen the immune system.

Today, this kind of building aesthetics recreated by solid wood is highly required all over the world, especially for those who want a country or rustic style. In addition, as time passes, wood tends to get darker and Chestnut, in particular, reaches a brown coloration: this style is really demanded in the luxury market and prestigious real estate sector.

Solid Wood is not Hardwood

Now we want to define the difference between solid wood and hardwood. In the first part of the article we introduced the internal characteristics of a chestnut tree trunk, the heartwood and the sapwood. Let’s see how these represent the big difference between the two types. Solid wood is obtained by exploiting both the heartwood, the hardest part of the trunk, and the sapwood, consisting of the outermost rings. This part of the trunk is less dense (lower specific weight) and softer with a higher possibility of deformations and anomalies over time. Solid wood, instead, is made only from the innermost layer, the heartwood, which is harder and more resistant so that it always remains homogeneous and compact

Solution to Seasoning Times

Solid Chestnut requires very long seasoning times before it can be used in its many applications. Seasoning is a process in which the wood is stabilized and loses most of the water left inside, which could be the cause of deformation and instability. The process can be carried out either naturally or artificially, through special furnaces for drying purposes. Artena Legnami® uses specialized furnaces in order to avoid the long natural seasoning times, guaranteeing the same quality standards as natural processes but in a much shorter time and thus offering solid chestnut products all year round.

Click HERE to learn more about the structural use of our Premium Italian Chestnut®. Also, follow us on our Facebook and Instagram pages for news and insights on the Chestnut Culture.

Don’t miss our other publications:

THE ECONOMY OF CHESTNUT

THE POWER OF TANNIN

A CHESTNUT RECORD

BACK TO THE WOOD