HOW TO MEASURE THE QUALITY OF CHESTNUT

Defining the quality of a material or product is not easy at all.

In the world of commerce, globally speaking, there are many products that are provided and promoted as quality goods, trying to justify that in the most disparate ways, especially if there is no certifications that may attest their value, compared to other products.

As a label, the quality is worth 0 for customers and consumers if a comparison system of product values with other alternatives has not been properly defined. A classification that highlights the advantages which are measured through specific parameters and used to verify the real level of efficiency.

Not all products or services in the Great Economy require particular technical characteristics so to be chosen by the customer. However in other instances, it is the exact performance value of a given product that decides the sell process because if it does not conform to certain values, often, it cannot be suitable for use. We may refer to the world of construction and the sectors of architecture, building, civil and environmental engineering, etc, for instance.

A material suitable for structural application must be submitted to rigorous controls and checks in order to receive a certification attesting to its actual quality and performance capacity. Among many products on the market, there is one in particular that requires a series of controls starting from its natural state: that’s wood!

When WOOD becomes TIMBER

There are about 30,000 known wood species in the world. Only a few hundred are suitable for trade and only a few of these can be considered for structural use. From the plant cultivation, which is regulated by regional standards, and the accurate selection of the troches with the relative traceability of their origin, to the first production process by specialized centers that must follow specific National and European procedures.

During the last stages of this process, the material literally changes its identity. Wood, meaning the raw material, becomes Timber, a product for structural use. This happens only after it has been classified according to its resistance, made suitable with a series of performance values and finally delivered by a specific producer or a qualified processing center.

Values, Performance and Parameters

The classification of timber strength is governed, therefore, by a series of performance parameters that refer to a specific value. Each technical characteristic is statistically recorded on the basis of the results of destructive tests and experiments carried out in the laboratory.

Among the species, before mentioned, designated for structural use, there is the Italian Chestnut. It has its own evaluation process and registers specific values in relation to parameters. Some main values are listed below:

– Flexural strength

– Shear strength parallel to grain

– Shear strength perpendicular to grain

– Compression parallel to the grain

– Compression perpendicular to the grain

– Modulus of elasticity parallel to grain

– Modulus of elasticity perpendicular to grain

– Volumetric mass

The respective values can be found on the in-depth page of our Solid Chestnut.

However, how are these values established? And how can we measure these values?

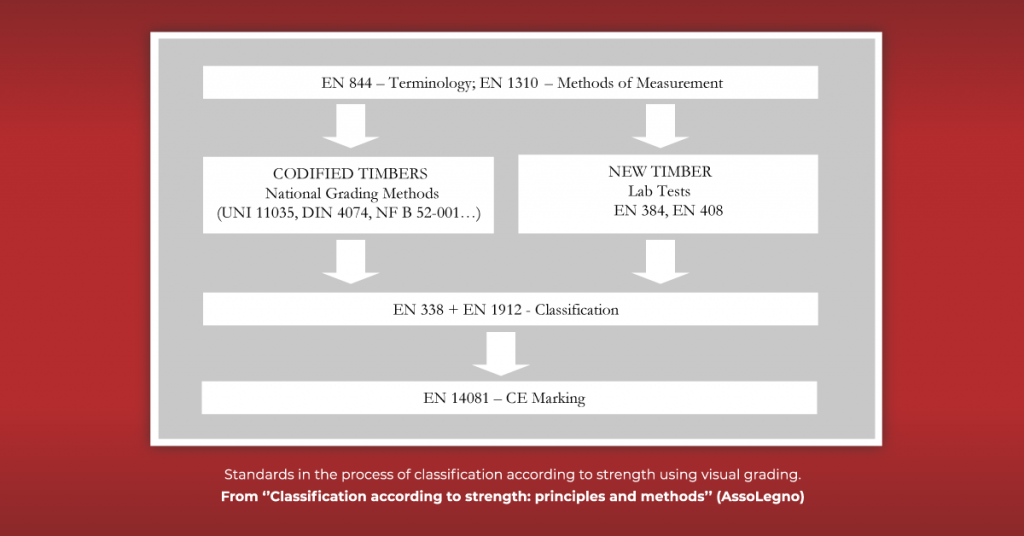

Visual Grading Classification

In Italy, the main method for the classification of strength is the “visual grading” method through manual measurements of the wood characteristics that are able to influence the mechanical properties of a structure. The rules of visual grading have been defined and codified in technical standards which are shared by operators of various origins (sawmills, designers, insurance companies and government agencies) and validated after years of application experience, both in Europe and in North America. A dynamic process that is necessary in order to always guarantee the levels of reliability and safety required of the structures. Levels that the products of Castagno Strutturale have always guaranteed.

But, in addition to the system of visual grading for the efficiency of the product, recent studies on Chestnut wood have allowed Artena legnami® and all companies from the ConLegno consortium, to obtain a European Technical Evaluation (ETA) aimed at the CE marking of the assortment known as “Uso Fiume of Chestnut”.

Uso Fiume of Chestnut

Our journey from the performance parameters, the quality lab-tested and the next classification of the structural product, officially ends with the certification of the most effective assortments for structural application. The CE marking for the “Uso Fiume of Chestnut”, in particular..

By definition, these products are obtained by four-sided squaring of selected logs, preserving the natural bevels so as to limit the interruption of fiber continuity in the manufacturing process.

Assigning precise and reliable mechanical resistance values to these products means offering a basic instrument of analysis to designers and end customers, enhancing the use of an Italian forest product, combining aesthetic taste and technique in the renovation of historic buildings and in modern constructions too.

Click HERE to discover the CE certification for “Uso Fiume of Chestnut” of our Premium Italian Chestnut ®.

Click HERE to learn more about the structural use of our Premium Italian Chestnut®. Also, follow us on our Facebook and Instagram pages for news and insights on the Chestnut Culture.

Don’t miss our other publications:

7 REASONS TO CHOOSE SOLID CHESTNUT

THE ECONOMY OF CHESTNUT

THE POWER OF TANNIN

A CHESTNUT RECORD

BACK TO THE WOOD